The ESS does not need OOB motors to perform Height Control. We wrote everything from the ground up (for Height Control in Mach4) and Mach4 has nothing to do with Height Control when the ESS is used with a WarpRunner, TMC3in1 or an Up / Down H.C.

Q3: Are OOB (Out of Band or non coordinated) motors required with the WarpRunner and ESS?Ī: Out of band motors are only required for the way Mach4 handles Height Control, without the ESS. This process loop the repeats continuously. The ESS responds to the commanded velocity and makes the Z axis move and then reports the Z positions back to Mach4. On/Off button, Arc Okay, and all the other Anti Dive modes) then the WarpRunner will compare the current tip voltage to the target tip voltage 2'500 times per second and command a Z axis velocity up or down to get the two voltages to match. If Height Control is allowed ( by the H.C. Q2: How does the WarpRunner and ESS perform Height Control?Ī:The WarpRunner measures the current (actual) tip voltage over 187'000 times every second and filters that data down to about 2'500 data points per second. Please just believe us and use Mach4 and SheetCam.

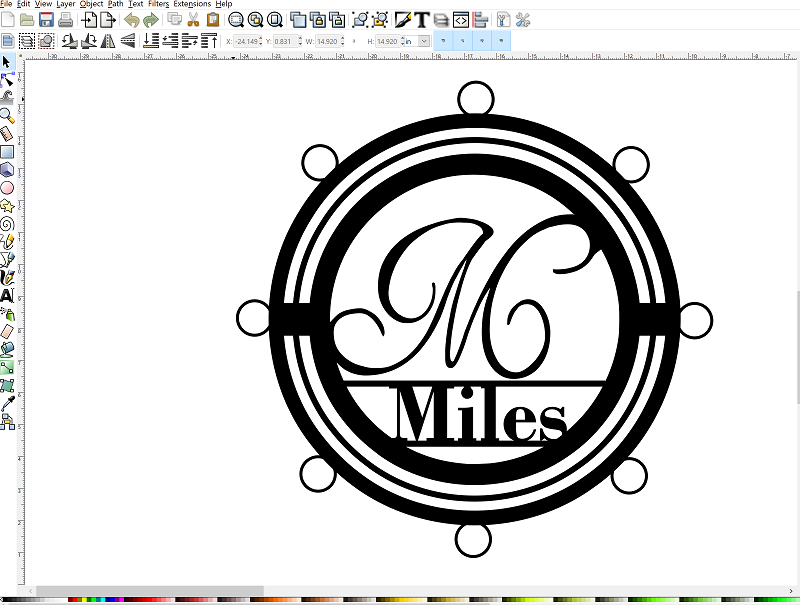

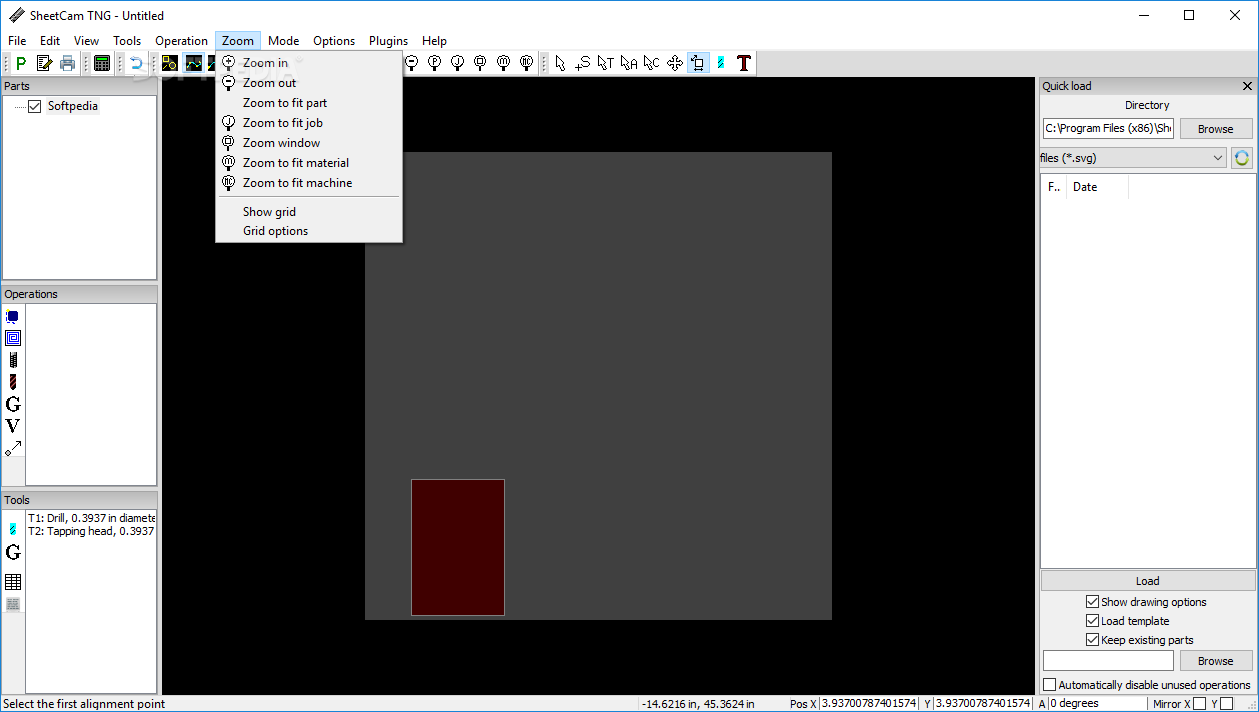

Rotate sheetcam full#

I have to build 2 of the square tube ones and will have to be full 5 axis machines as i need it to cut at an angle on some parts, the torch will have to rotate. And cutting any kind of design features messes the dimensions badly.

It will have trouble on the upslope and downslope as the material will be at a very sharp angle and moving faster than when cutting the side. I did test using a 3 axis to cut square tube, and it does work if the Z axis and THC are very fast, but not good. Since i have built several tube cutters for round tube, they are 3 axis machines and LinuxCNC does not care much that one of the linear axis is actually a rotary one, it works perfectly, and there is no need for THC at all if everything is set correctly.īut square tube has sharp corners and that messes up the material speed a lot making the use of the 4th axis a must, but again can be used without a THC. Please Log in or Create an account to join the conversation.

I saw that post about a month ago when Tom said something about cutting square tube.ĭo you think Les was talking about a 4th axes in terms of one rotating the torch as it rounds the corner? say you are cutting at 2000 mm/sec, my rough calcs says your Z would need to accelerate at 1000 mm/sec/sec to follow it. If you have a good Z axis, I think it would be able to do it without crashing. It would be worth testing to see if the Plasmac THC can lift the torch fast enough to follow the surface. Just something to consider, best ask Les if you have any questions about it / his thoughts on the subject THC is best left off and run blind (no height control) with the z being controlled by gcode. Here is a recent post from Les at sheetcam on rotary + square tube (4 axis recommended, you can normally get away with 3 with a rotary axis as you can repurpose one of the axis to drive the rotary motion device stepper)į/viewtopic.php?f=2&t=8458#p28054

0 kommentar(er)

0 kommentar(er)